Computational Fluid Dynamics

What Is CFD and Why CFD Used?

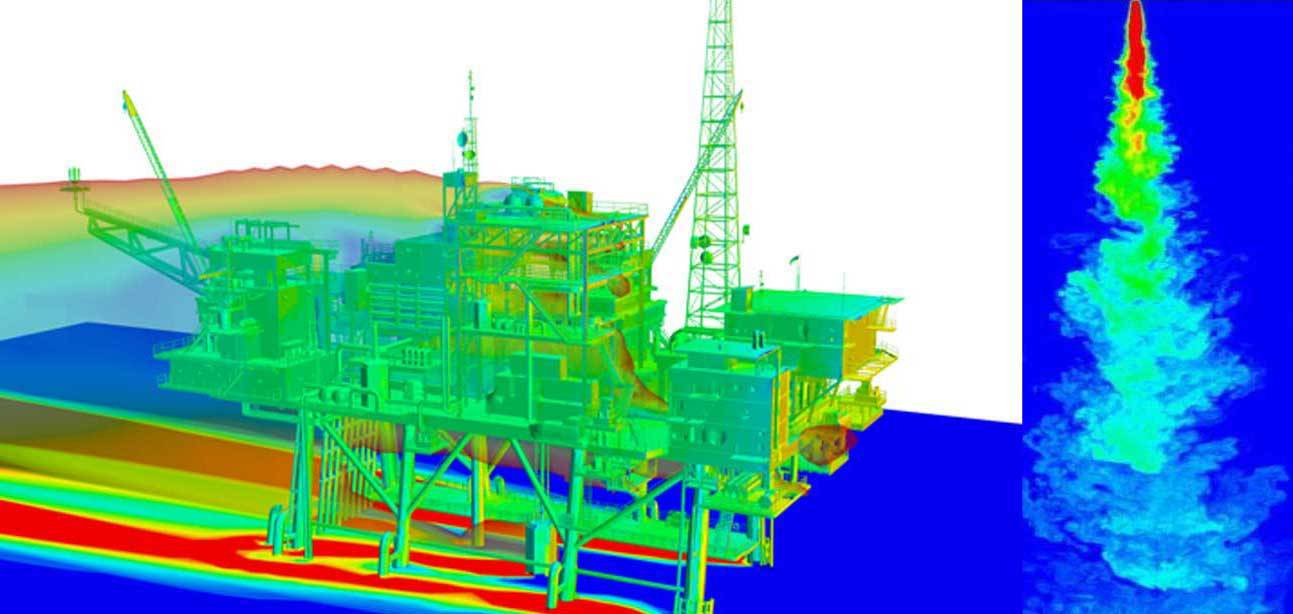

CFD is a powerful and versatile tool that can be used to visualise and analyse fluid phenomena. e.g. airflow, temperature, moisture content and particle size distribution.

CFD is used for gaining insight into any fluid flowing process. This allows optimization of various areas within your processes. CFD can also be used in validating new ideas for products/designs without interfering with daily operations.

By using its CFD capability AdiChem can speed up development thereby reducing the time to bring a new product to the market.

Benefits.

Improve and optimize the processes.Fast, accurate and cost-effective.

Improve product quality.

Tool to analyze challenging problems without affecting daily operations.

CFD capabilities.

AdiChem provides process performance enhancement as well as product development solutions. AdiChem has extensive expertise and experience in utilizing a wide range of computational and experimental models to solve challenging problems within the industry e.g. complex flow.

Our CFD experts are always ready to assist you with new process development challenges. They can help you to find smarter and cost effective processing solutions.

Also, these experts can do multiple simulations in parallel, which helps reduce the time for your development.

CFD can be used as a tool to optimize your existing process. Our CFD experts are able to model your existing plant and come up with improvements.

CFD applications.

Flow analysis.

Temperature distribution.

Particulate flow.

Particle size distribution.

Chemical kinetics reactions.

Equipment analysis and validation.

Process equipment design.

Solving trouble shooting problems.

Applications in Chemical Engg

Combustion

Evaporation

Cavitation

Solid drying systems

Droplet separation

Packed bed reactors

Cyclone separators

Mixers

Bubble columns

Fluidized bed systems

Particulate systems

Dust collection systems

Solid suspensions

Speed up the new process development

Modern CFD tools and large computer power allows for fast screening of different designs

CFD can be used for complete Process development